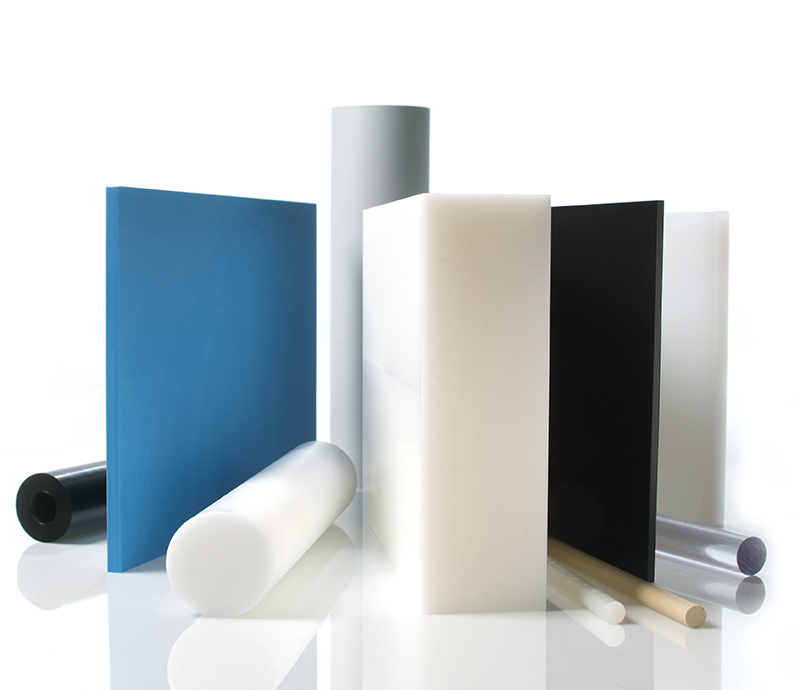

Engineering materials, Nylon, Acetal, PTFE and Phenolics are just a few of the items we can offer, with our specialists supply partners we are able to provide a wide range of services including machined parts.

Acetal's Applications include: bushes, bearings, rollers, pulleys, electrical insulation and wear strips. It is mainly available as rod and sheet and has the following characteristics; Low moisture absorption - Excellent dimensional stability - High mechanical strength - Lower friction coefficient than Nylon. Commonly referred to by the trade name Delrin.

Nylon is used for mechanical parts such as machine screws, gears and other low- to medium-stress components previously cast in metal. Engineering grade nylon is processed by extrusion, casting, and injection moulding. Nylon 6 offers great mechanical strength, stiffness, wear and shock resistance whilst 6.6 is harder, more rigid than Nylon 6 and is easier to machine. We supply the material in rod and sheet form.

Phenolic laminates are made by impregnating one or more layers of a base material such as paper (SRBP), fiberglass or cotton (SRBF) with phenolic resin and laminating the resin-saturated base material under heat and pressure. Paper phenolics are used in manufacturing electrical components. Glass phenolics are particularly well suited for use in the high speed bearing market. These materials are often referred to by specific trade names such as Tufnol®, Paxolin®

PTFE Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene. Being hydrophobic, non-wetting, high density and resistant to high temperatures, PTFE is an incredibly versatile material with a wide variety of applications, though it's perhaps best-known for its non-stick properties.